Your Reliable Scaffolding Sale & Rental Company in Singapore

- Best Quality – CE( EN1090 & ISO3834) &ISO9001

- Competitive Scaffolding Equipment Price

- Door to Door Scaffolding Delivery

- Sell or Rental

- Program planning and design

Why Choose us

Our Certificates

EN 1090 CERTIFICATION

EN 3834 CERTIFICATION

EN 12811 CERTIFICATION

Mission: Make all Projects Safer & Easier

Rapid S.E.A Ensures Your Scaffolding Equipment Quality & Safety

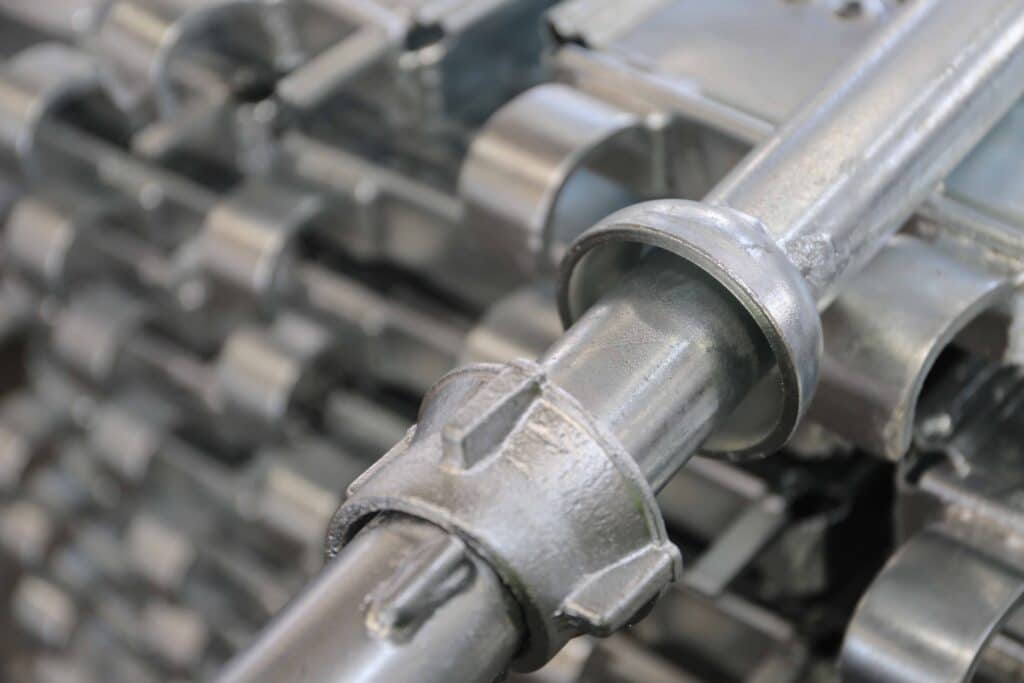

Scaffolding Welders are Certified By BS EN 9606, ISO 5817, ISO15614 & NDT. RapidSea Scaffold Factory is Accredited By EN1090-1:2009 & CE. Our Factory Has its Own Scaffolding Testing House with Complete Test Facilities.

Featured Products

Trust Us for All Your Scaffolding Needs

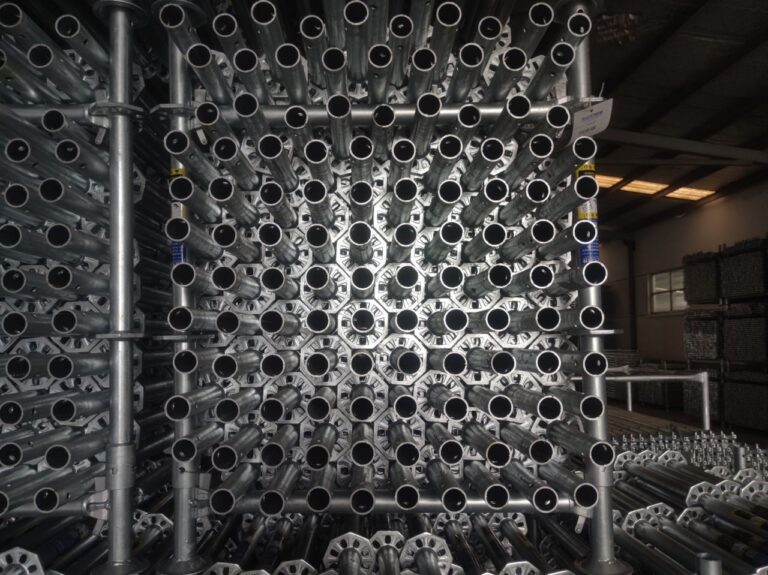

Rapid Sea’s premium scaffolding, formworks, and shoring systems – designed and manufactured with quality and safety in mind. Our products are crafted to meet international standards, ensuring that your building projects are safe and efficient. Choose from our wide range of scaffoldings, formworks, ringlock and octagonal systems, or let our team design a custom solution for your specific needs.

With strict quality control and factory inspections, we guarantee timely delivery of only the highest quality materials. Trust Rapid Sea for all your scaffolding needs.

Our experience

Full Range Scaffolding Equipment Supplier

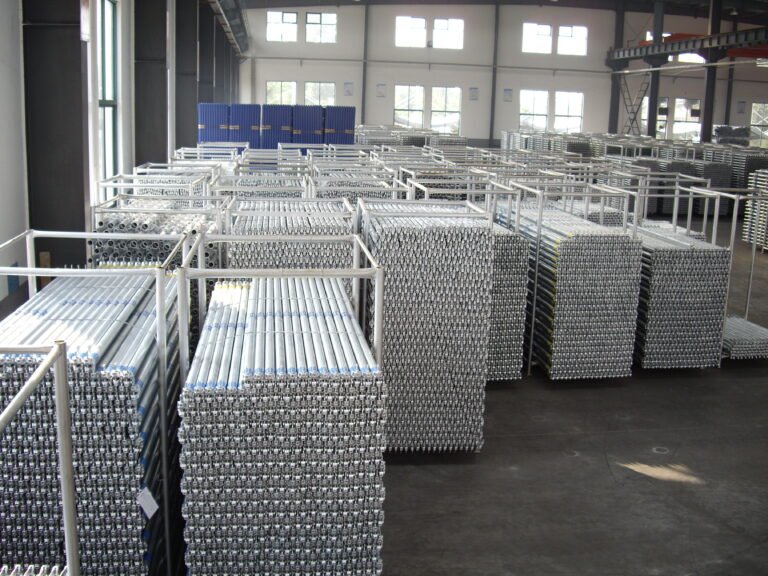

Exporting to 56 Countries, RapidSea is The Most Famous OEM Scaffolding Equipment Manufacturer. Supplies Germany, UK, USA Scaffolding and Formwork Companies for 20 Years.

Whatever Scaffolding Equipment You Want to Buy, RapidSea Is Your Best Choice: Easy Scaffolding System, Economy Scaffolding Products, Durable Scaffolding Items, Light Weight Scaffolding Pieces & Accessories, Galvanized Scaffolding Materials, Painting Scaffolding Frames, and Custom Scaffold Towers etc.

Our Blog

Latest Articles

Free Consultation

Get A Quote