Curious about scaffold planks – their sizes, standards, and terminology? Look no further! Let’s explore the world of scaffold planks and uncover the essential details behind these crucial components of construction projects.

Table of Contents

ToggleWhat Size Plank is Required for Scaffolding?

Determining the appropriate size of scaffold planks is crucial for ensuring safety and efficiency on construction sites. Standard sizes typically range from 6 to 16 feet in length and 9 to 12 inches in width. However, it’s essential to consider factors such as load capacity and project requirements when selecting the right size for scaffolding applications.

What is the Standard Scaffold Plank?

Often referred to as scaffold boards or scaffolding platforms, standard scaffold planks serve as the backbone of scaffolding structures. These planks are meticulously engineered to withstand the rigors of construction work while providing a secure and stable platform for workers. Adherence to industry standards and regulations is paramount to ensure the safety and reliability of scaffold planks on job sites.

What Are the Planks on Scaffolding Called?

Planks used on scaffolding are commonly referred to as scaffold planks, scaffold boards, or scaffolding platforms. Regardless of the terminology, their primary function remains consistent – providing a safe and stable working surface for workers to perform their tasks at various heights on construction sites.

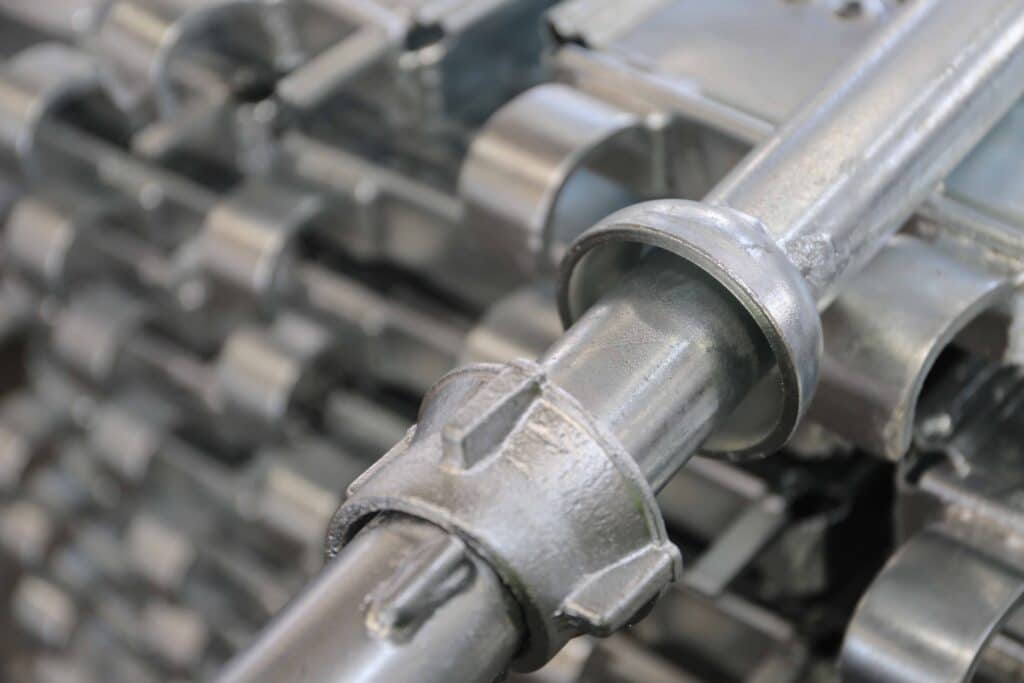

Exploring Different Types of Scaffold Planks

Scaffold planks come in various types, each offering unique features and advantages to cater to different project requirements. Wood scaffold planks, known for their affordability and versatility, are widely used in construction. Aluminum scaffold planks offer lightweight yet durable solutions, ideal for projects requiring portability. Metal scaffold boards provide robust support for heavy-duty applications, ensuring stability and reliability. Scaffold planks with plywood decking combine the strength of metal or aluminum frames with the enhanced grip and durability of plywood surfaces, offering optimal performance and safety on job sites.

Factors to Consider When Choosing Scaffold Planks

Several factors should be considered when selecting scaffold planks for construction projects. These include load capacity, material durability, adherence to safety standards, and project-specific requirements. By prioritizing these considerations, construction professionals can ensure the safety and efficiency of scaffold planks on job sites, minimizing risks and maximizing productivity.

Understanding the Varieties of Scaffold Planks

Scaffold planks come in a myriad of types, each tailored to specific project requirements. Wood scaffold planks, prized for their affordability and versatility, remain a popular choice in construction. Aluminum scaffold planks offer a lightweight alternative without compromising on durability, ideal for projects requiring portability. Metal scaffold boards provide robust support for heavy-duty applications, ensuring stability and reliability on the job site. Additionally, scaffold planks with plywood decking combine the strength of metal or aluminum frames with the enhanced grip and durability of plywood surfaces, offering optimal performance and safety.

Material Composition of Scaffold Planks

The material composition of scaffold planks varies depending on the type and manufacturer. Wood scaffold planks are typically crafted from high-quality timber, ensuring strength and durability. Aluminum scaffold planks feature lightweight yet sturdy aluminum alloys, providing a perfect balance of portability and resilience. Metal scaffold boards are constructed from durable metals such as steel, offering exceptional load-bearing capacity and longevity. Scaffold planks with plywood decking feature a combination of metal or aluminum frames and plywood surfaces, delivering enhanced grip and stability for workers.

Scaffold Planks in the Singapore Market

In the dynamic construction landscape of Singapore, scaffold planks play a pivotal role in ensuring safety and efficiency on job sites. While various types of scaffold planks are available, wood scaffold planks remain the preferred choice for many construction professionals due to their versatility and cost-effectiveness. However, aluminum scaffold planks are gaining traction, especially for projects that require lightweight yet durable solutions. Regardless of the type, scaffold planks used in the Singapore market must adhere to stringent safety standards and regulations to ensure compliance and mitigate risks.

Meeting Standards in the Singapore Market

Scaffold planks used in the Singapore market must meet rigorous standards to uphold safety and quality. Key standards include compliance with the Workplace Safety and Health (WSH) regulations, adherence to industry best practices, and certification from recognized authorities such as the Building and Construction Authority (BCA) and the Ministry of Manpower (MOM). Additionally, scaffold planks should undergo regular inspections and maintenance to ensure optimal performance and longevity in demanding construction environments.

In conclusion, scaffold planks are essential components of construction projects in Singapore, offering stability, safety, and efficiency for workers. By understanding the diverse types, materials, and standards governing scaffold planks, construction professionals can make informed decisions and uphold industry best practices, ensuring the success of their projects in the dynamic Singapore market.